Contents

- Introduction to PDCA

- Stages of the PDCA Cycle

- Application of the Deming Cycle

- Advantages and Disadvantages of PDCA

Introduction to PDCA

The PDCA cycle, also known as the Deming cycle, is a methodology designed for continuous improvement of products and optimization of business processes. Named after its creator, Edward Deming, this cycle was developed in the 1950s and is based on the business management concept proposed by another notable economist, William Shewhart. The main idea of this approach is that quality is a defining factor for business success. To enhance quality, it is necessary to continually improve individual processes. For instance, to increase sales, it is essential to improve all stages of the sales funnel, optimize recruitment and training processes, and test new tools.

The PDCA cycle consists of four key steps: Plan, Do, Check, and Action. Deming also suggested replacing the Check step with Study, which sometimes leads to the cycle being referred to as PDSA: "Plan, Do, Study, Act." It is important to note that PDCA should not be confused with another four-step cycle known as HADI ("Hypothesis, Action, Data, Insights"), which is used for testing new ideas and identifying growth points but is not suitable for optimizing complex business processes.

Stages of the PDCA Cycle

1. Planning (Plan)

At the first stage of the PDCA cycle, the following aspects need to be defined:

- Establish a goal: what and why needs to be changed in the business operations;

- Identify the reasons hindering the achievement of the desired outcome;

- Formulate a hypothesis;

- Create an action plan;

- Define metrics for assessing progress and results (KPI).

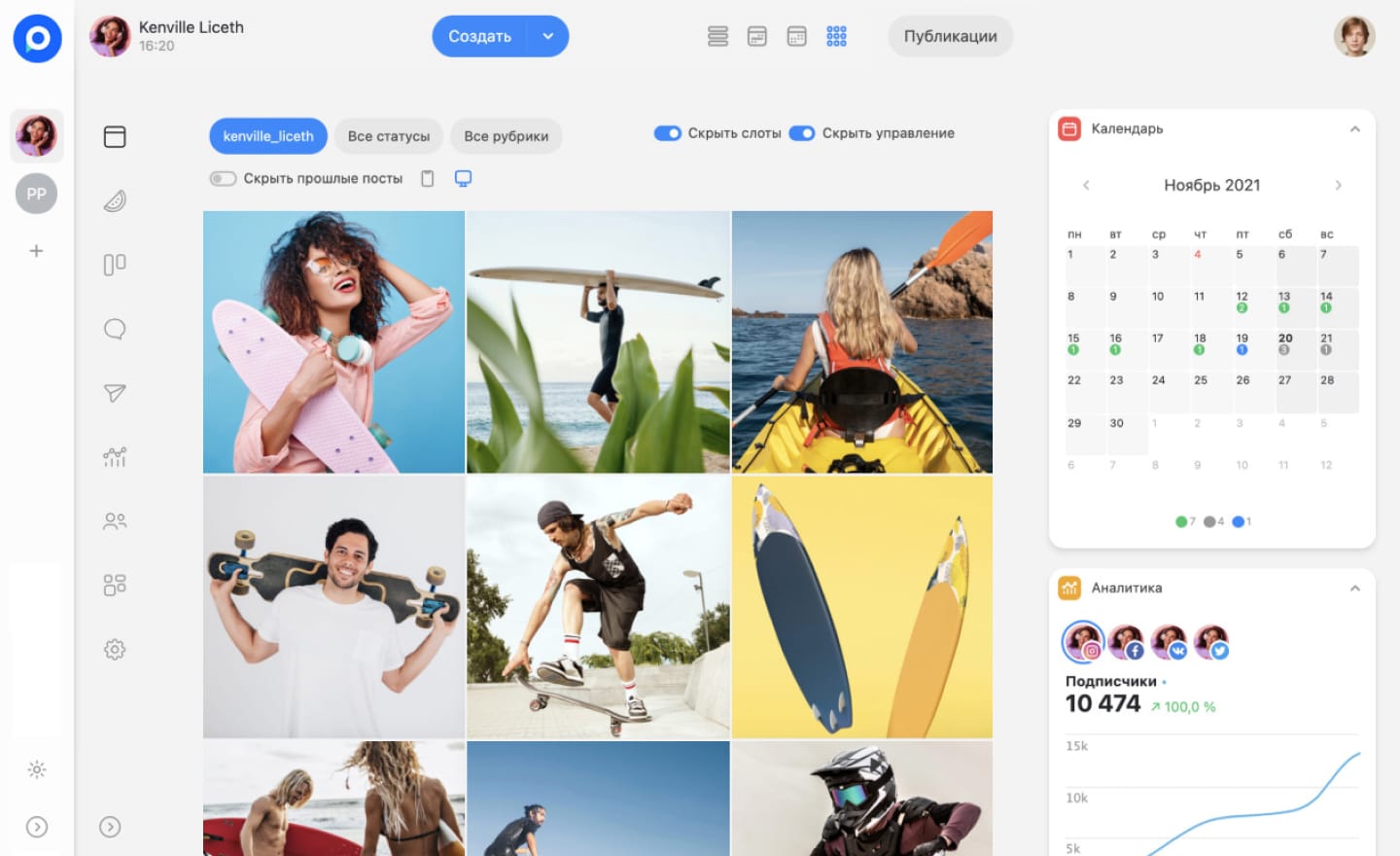

For example, if a company promotes its services through social media but notices a decline in the channel's effectiveness, it may conduct research to determine what exactly is unsatisfactory for visitors. Based on this, the content plan can be updated to include more visual content that can help restore sales to previous levels.

2. Doing (Do)

At this stage, it is important to communicate the goals and key ideas of the plan to the employees. Key points of execution include:

- Implementing changes on a small scale (test sample and small budget);

- Documenting not only successes but also failures;

- Adjusting the plan if certain decisions are not working.

For instance, a company may create a new content plan and to test the new format, publish content twice a week while collecting statistics on views and conversions.

3. Checking (Check) or Studying (Study)

This stage involves analyzing interim results:

- Collecting metrics from the test implementation;

- Comparing results with expected KPIs;

- Continuing to execute the plan if KPIs are achieved; otherwise, returning to the starting point to develop a new plan.

For example, after a month of work, a company may gather data and find that while views have increased, the desired metrics have not been achieved. In this case, analysts may identify that the problem lies in the inappropriate tone of the content, which requires adjustment.

4. Acting (Action)

At the final stage, it is necessary to evaluate the effectiveness of the changes. If the results are positive, then:

- Results are solidified in standards and guidelines;

- A system is developed to maintain new functions;

- Other areas for improvement are sought.

If the results are unsatisfactory, resources should be reallocated, and preparation should be made for a new iteration based on new data. For example, a company may keep the new formats but change the content to better meet the expectations of the target audience.

Application of the Deming Cycle

The PDCA cycle is a universal model that allows breaking down large tasks into smaller stages, making it easier to monitor their execution. PDCA is applied in various scenarios:

- Launching a new product: Developing a concept, implementing a prototype, gathering feedback, and optimizing.

- Implementing new business tools: Testing on a small group to minimize risks.

- Improving existing processes: Optimizing processes to enhance customer satisfaction.

The PDCA cycle can be applied not only in business but also to achieve personal goals, such as improving time management.

Advantages and Disadvantages of PDCA

Advantages

- Universality: Applicable in any field.

- Simplicity: Consists of only four stages.

- Flexibility: Allows for quick corrections of mistakes.

- Employee Involvement: Employees participate in the improvement process.

Disadvantages

- Duration: May require many iterations to achieve goals.

- Lack of Guarantee: Not suitable for projects where precision is crucial from the first attempt.